Pinboards & Whiteboards

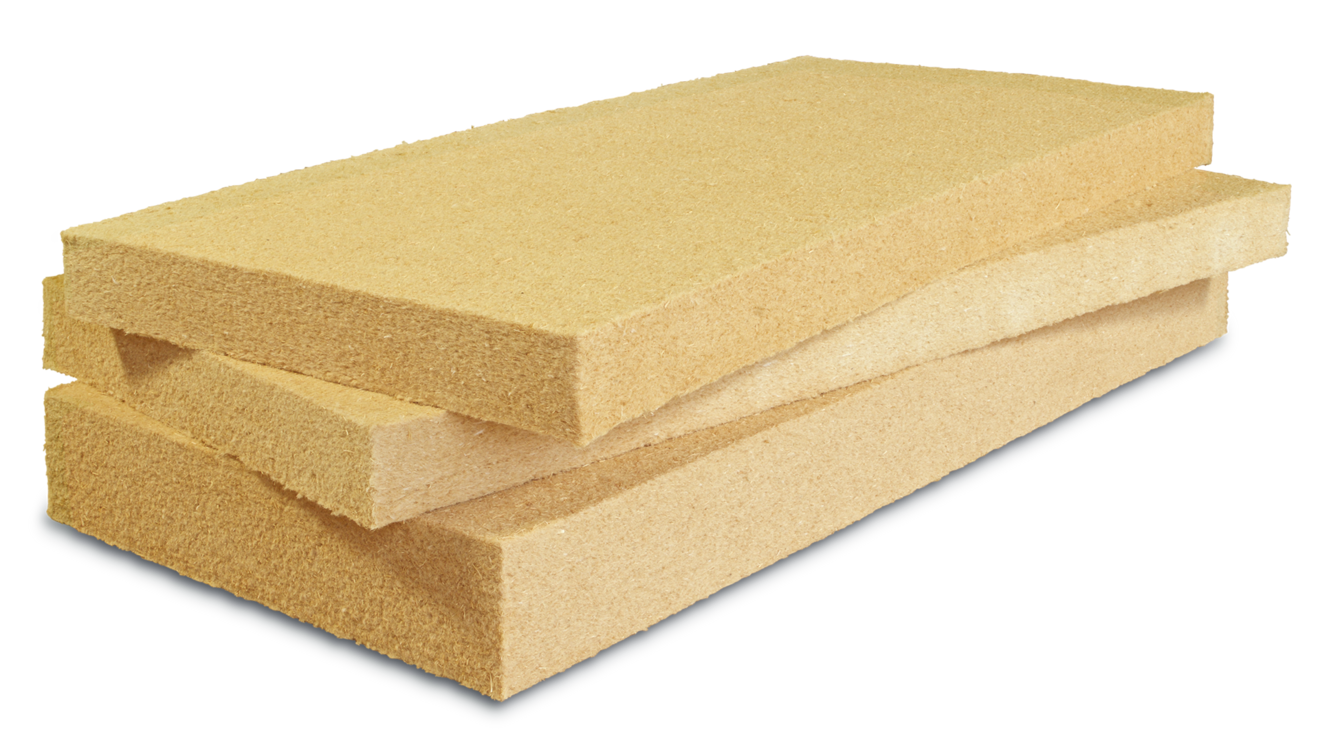

Stability, ecology and durability

STEICOstandard nature is a stable woodfiber softboard made using the wet process. The board is bound by the wood's own lignin - without the addition of external adhesives. The board can be produced grinded on one side. This provides a bright surface with good density tolerance and precise thicknesses. The panels are available in thicknesses from 8 to 19 mm and are thus ideally suited as core material (under covering) for pinboards and whiteboards.

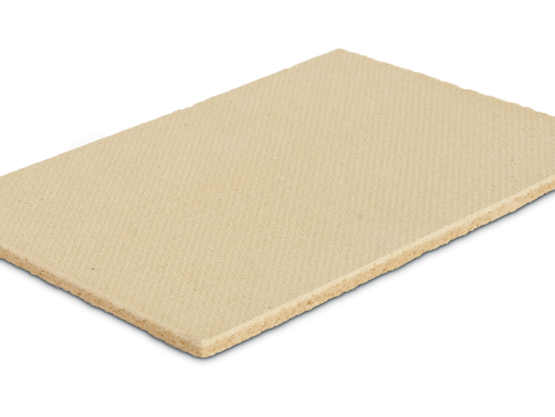

Wood fiber board for visible application

STEICOivory faced is a stable woodfiber softboard made using the wet process. The board is bound by the wood's own lignin - without the addition of external adhesives. The panels are available in thicknesses from 8 to 19 mm and are thus ideally suited as core material. The special feature is the Biboard technology. The boards are given a particularly stable, ivory-colored top layer, which allows them to be used without additional coverings such as textile or similar.

Downloads

Ecology, economy and social responsibility

Sustainable forestry

STEICO only processes wood from sustainable forestry, certified according to the strict rules of the PEFC.

Annual sustainability Report

As sustainability is part of STEICO's "corporate DNA", STEICO publishes an annual report, in which all aspects of ecological, economic and social sustainability are presented - in accordance with the specifications of the recognised reporting standard of the Global Reporting Initiative (GRI).

Loose woodfiber

Loose woodfiber for various industrial applications.

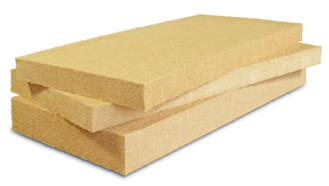

Stable LDF woodfiber softboards

Low density fiber woodfiber softboards (LDF) made out of the dry process

STEICOflex

Flexible wood fibre insulation mat. Best insulation value of all natural insulation materials.

Laminated Veneer Lumber (LVL)

Exceptionally load-bearing and dimenionally stable engineered wood product

Hardboard HB

Stable hardboard for versatile applications.

Woodfiber softboards (wet process)

Versatile woodfiber softboard made out of the wet process