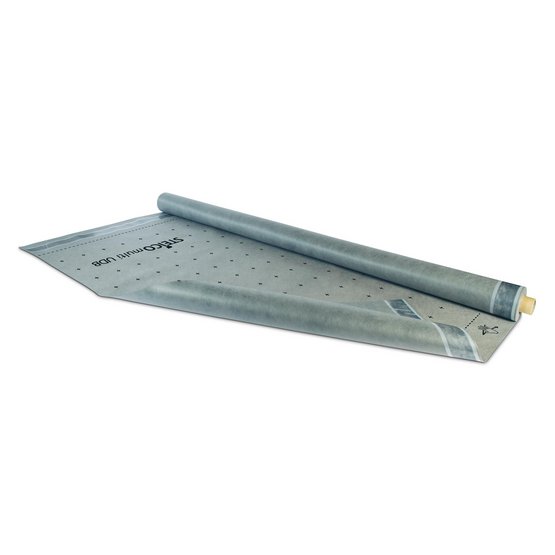

STEICOmulti UDB

Highly vapour-permeable airtight membrane

Highly vapour-permable airtight membrane, sarking membrane and roofing underlayment

- 3-layer, tear-resistant and flexible

- 2 integrated self-adhesive areas

- Airtight, highly vapour-permeable and resistant to driving rain

- Outdoor exposure of up to 3 months possible

Product sheet

Characteristics

| Production and designation | EN 13859 |

| Fire class (RTF) according to EN 13501-1 | E |

| Area weight [g/cm²] | 165 |

| sd value [m] | 0,02 |

| Temperature resistance [°C] | -40 to +80 |

| Max. tensile force longitudinal | 290 |

| Max. tensile force transverse | 210 |

| Elongation at Max. tensile force longitudinal [%] | 50 |

| Elongation at Max. tensile force transverse [%] | 90 |

| Tear resistance longitudinal [N] | 220 |

| Tear resistance transverse [N] | 280 |

| Resistance to water penetration | W1 |

| Seepage resistance after artificial ageing | W1 |

| Outdoor exposure | 3 Months |

| Suitable as a temporary roof cover | 4 Weeks |

| Resistance to air penetration [m³/m²] | ≤0,04×h according to EN 12114 |

| Minimum roof pitch [°] | ≥10 ° depending on the standard roof pitch of the roofing |

Dimensions

Length [mm] |

Width [mm] |

Area/roll [m²] | Area/pal. Net [m²] | Number/pal. [pcs.] |

|---|---|---|---|---|

| 50000 | 1500 | 75 | 1500,000 | 20 |

| 50000 | 1500 | 75 | 1500,000 | 20 |

Processing STEICOmulti UDB

- Lay the membrane or sheet so that the printed side is facing the fitter

- Lay the membrane or sheet parallel to the eaves starting with an overlap of at least 10 cm

- Fix the membrane or sheet in place solely within the overlap area (e.g. clips)

- Activate the longitudinal self-adhesive areas by removing the protective strip only after the membrane or sheet has beed fixed in place

The following also applies when used as an airtight membrane:

- Ensure flush-mounted bay insulation (no cavities may exist under the STEICOmulti UDB)

- Sufficiently thick insulation covering with STEICOspecial/STEICOspecial dry and STEICOuniversal/STEICOuniversal dry must be carried out; for additional details see "Konstruktionsheft Steildach" (inclined roof construction booklet)

- Component joints and penetrations must be made in an airtight manner by means of STEICO system accessories

- Additional information can be found in the seperate processing instructions for STEICOmulti UDB

(Please refer to the product data sheet for detailed information)

Declaration of performance